The right code of the BEM for battery replacement

Different ways of battery coding

Nowadays we can see in the market that OE car manufacturer follow different strategies to reprogram new batteries in their vehicles BMS.

SELF LEARNING: As a first group there are self-learning systems. Here the BMS comes with only one or a few preprogramed battery options per vehicle which the BMS will use as a reference. After battery replacement the BMS compares over the time the actual new battery performance with the battery references stored in the BMS memory and will learn which of the stored references fits to the actual measured performance. OEs following this strategy are for instance Abarth, Alfa Romeo, Chevrolet (Daewoo), Citroen, Dacia, Fiat, Honda, Lancia, Mercedes, Mitsubishi, Peugeot, Renault, Subaru, Suzuki, Toyota and Volvo.

REGISTRATION WITH DIAGNOSTIC TOOL: A second group of OE car manufacturer require an active registration of the new replacement battery into the vehicles BMS and with it the use of a diagnostic device for reprogramming. Just to give some examples we can name Alpina, Audi, BMW, Jaguar, Jeep, Land Rover, Mazda, Mini, Seat, Skoda and Volkswagen. And within this group some vehicle manufacturers like the VAG group or BMW require a code to register the new battery during replacement. The codes are not only OE but also battery specific.

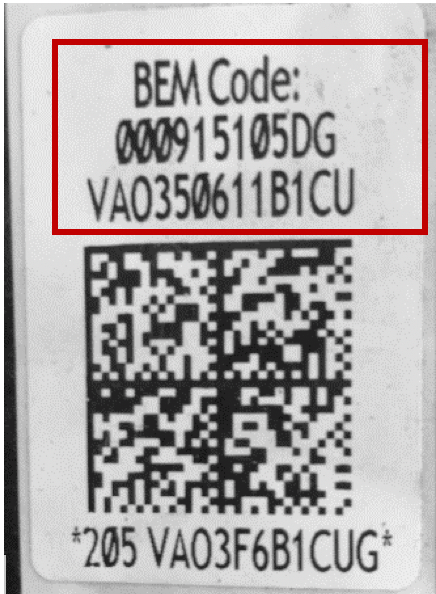

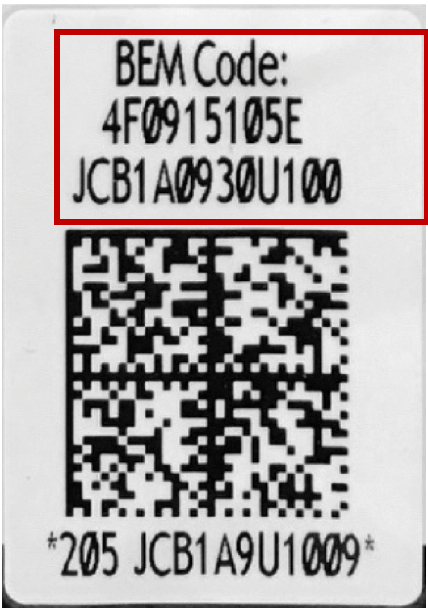

The VAG specific BEM code is basically a two line code. The first line contains the OE spare part number. This number is different for OES (i.e. 000915105DG) and OEM (i.e. 4F0915105E) channel but limited to the amount of battery types VAG uses. The second line codes the battery manufacturer, the manufacturing date of the battery and contains a part making this code specific.

OES BEM-Code

OEM BEM-Code

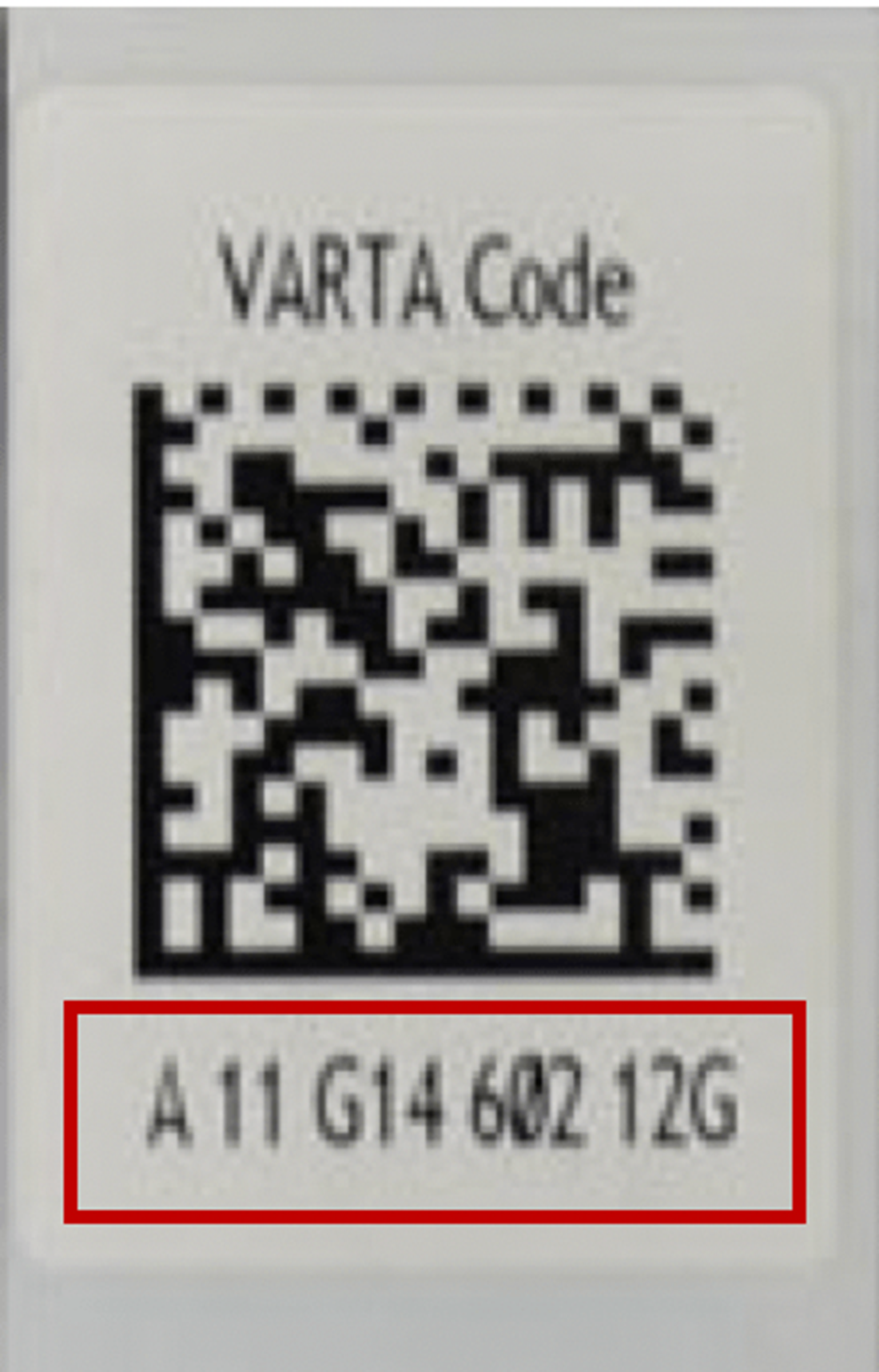

NOTE: The QR code printed on the VARTA® AGM and EFB batteries is used for internal purposes only. It does not contain the same information as an OE BEM code, and therefore cannot be used as a replacement of the OE BEM code to register new batteries in VAG vehicles.

Depending on the IAM diagnostic tools some request the BEM code for battery replacement. In this case for VAG it is required to insert both lines of the BEM code of the new battery.

Others diagnostic tools like Hella Gutmann or BOSCH KTS create the required battery specific information using drop-down options. Entering the BEM code is not required. You just need to select the capacity, manufacturer and technology. The serial number requested is just for traceability purpose. Any 10 digit number can be applied.

The following example shows a battery coding in a Škoda KODIAQ 1.5 TSI using a BOSCH KTS diagnostic device. After vehicle selection you need to choose the menu path for battery replacement and use the right parameter from the drop-down.

By running this process the monitored battery usage counter in the BMS will be reset to zero. Regarding battery capacity and technology we always recommend a ‘like-for-like’ or ‘better-for-like’ replacement. Never downsize the replacement battery!

Basically the same procedure is applied when using the Hella Gutmann diagnostic device.

If you use the VCDS for battery replacement in VAG vehicles or vehicles using VW technology there is a slightly different procedure depending on whether the vehicle is equipped with control unit 61. In this case you need to select control unit ’61 battery control’ and after that the right menu path. Here you can insert the needed OE spare part number and a 10 digit serial number. As we recommend to replace ‘like-for-like’ you can stay with the original OE spare part number if you replace the original battery with the same technology and performance. Slight deviations of the ratings is not a problem. If you replace ‘better-for-like’ you need to take the OE spare part number corresponding to the new battery chosen. For the requested serial number any 10 digit number can be applied.

In alternative it is also possible to reprogram the new battery into the vehicles BMS by selecting the battery parameters manually. The approach is quite similar to the BOSCH KTS or Hella Gutmann tools.

The following example shows this approach of battery coding in a Škoda KODIAQ 1.5 TSI using a VCDS diagnostic device.

By adjusting of one of the four battery values (capacity, technology, manufacturer, serial number) the monitored battery usage counter of the BMS will be reset to zero. The serial number always needs to be changed to address the new battery. But it is also possible to change the serial number back to the original one afterwards. So finally the new battery is programmed into the BMS but the original serial number stays.

COMBINED APPROACH: And there is a third group of manufacturers who follow both strategies dependent on the specific model. OEs to be mentioned are Ford, Hyundai, Kia, Lexus, Nissan, Opel, Porsche, Smart and Vauxhall

Battery coding without a tool

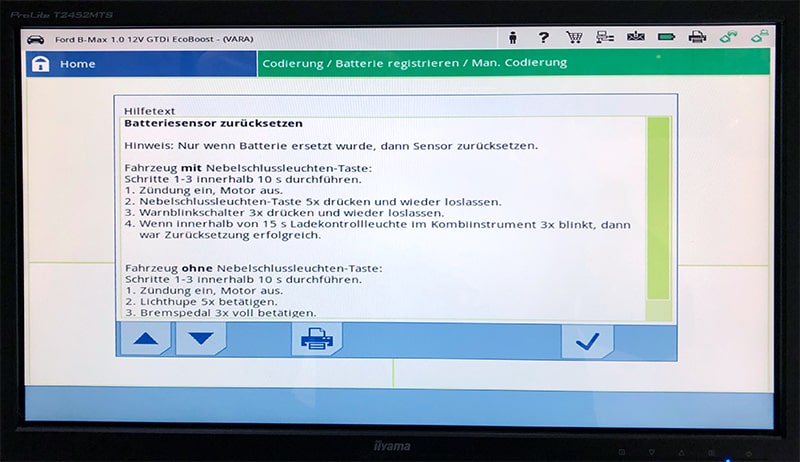

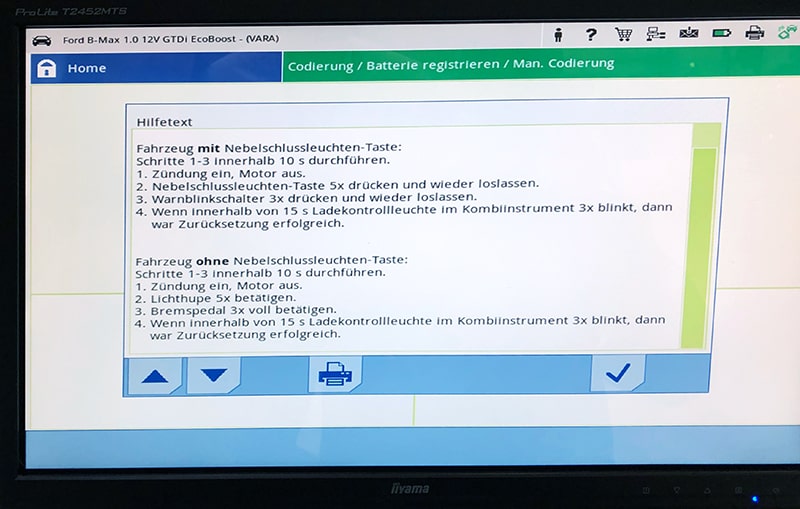

As a special case Ford needs to be mentioned as they offer for some models a BMS battery reset which not necessarily requires a diagnostic device. It can be done manually by a certain vehicle specific combination of dashboard buttons and switchers.

Vehicle with rear fog light:

- Switch on the ignition

- Press the rear fog light button 5 times

- Then press the warning flasher switch 3 times

If the red battery charge indicator light in the instrument panel flashes 3 times within 15 second the reset was successful.

Vehicle without fog light:

- Switch on the ignition

- Press the headlight flasher 5 times

- Then fully depress the brake pedal 3 times

If the red battery charge indicator light in the instrument panel flashes 3 times within 15 second the reset was successful.

This procedures reset the day count of the battery use. A fine calibration of the BMS is then made when the vehicle is closed for at least 3 hours.

Conclusion

You want to learn more about the different electrical systems in modern vehicles? Then our Advanced Automotive Training is definitely the right thing for you!

Find a trusted workshop

Do you work with batteries?

Deepen your knowledge

-

Construction of VARTA Promotive EFB Truck BatteriesA patented mixing element ensures that acid stratification cannot occur in our ProMotive EFB battery. Read our article now to find out exactly how this works and what advantages it brings.

-

The importance of charge acceptance of truck batteriesBatteries with high starting current (CAA) and sufficient capacity (C20) guarantee reliable fleet operation. We tell you why.

-

Battery tips for the leisure seasonGet ready for your journey. Discover helpful tips and tricks for your leisure battery to get the best start to the season.

Got a question?

-

Make use of our VARTA® Battery Finder to find the battery product that fits your vehicle.

It's important to understand that different lead-acid technologies are available, and proper functionality and long battery service life can only be guaranteed when the correct technology for your vehicle and usage profile is chosen.

-

43,22% (ADAC Pannenstatistik 2022: https://www.adac.de/rund-ums-fahrzeug/unfall-schaden-panne/adac-pannenstatistik/) of all vehicle breakdowns are caused by battery issues - make sure to eliminate those.

Find a trusted VARTA® Partner near you and get your battery checked!

-

To extend your vehicle's battery life, consider these tips:

- Charge Care: Regularly monitor and charge the battery, especially during long-term parking or winter storage. Charge every two months if used sporadically.

- Check Charge: Regularly check battery charge, particularly in cold weather or after short trips. Dimming headlights indicate low charge.

- Prioritize Safety: Conserve battery by minimizing non-essential electrical use and keeping safety systems active during long drives.

- Clean Installation: Keep the battery and terminals clean to prevent discharge and enhance charging efficiency.

For more information find our article "Correct battery care"