EFB Battery: Definition, Structure and Use in Vehicles

The Enhanced Flooded Battery (EFB) is a further development of the conventional lead-acid battery and is widely used in vehicles with basic start-stop systems. But what exactly distinguishes an EFB battery, and how does its structure differ from traditional battery types?

This article explains how EFB technology works, when its use makes sense, and what benefits it offers in everyday vehicle use.

What Does EFB Battery Mean?

EFB stands for Enhanced Flooded Battery. It is an improved version of the conventional wet-cell battery, specifically developed for vehicles with basic start-stop systems. Compared to traditional lead-acid batteries, EFB batteries are more cycle-resistant, have a longer lifespan, and offer better charge acceptance.

Unlike AGM batteries, which use a bound electrolyte absorbed in a glass mat, EFB batteries operate with a liquid electrolyte. Their performance is enhanced by materials such as a polyfleece scrim – a fibre layer applied to the positive plate that stabilises the active material and reduces shedding. This reinforcement improves cycle stability and extends service life.

What Role Does the EFB Battery Play in Modern Vehicles?

EFB batteries are built for vehicles with basic start-stop systems. They can handle frequent charge and discharge cycles without significant performance loss. Thanks to their improved cycle durability, they are particularly well-suited for city driving, frequent short trips, and vehicles with increased power demands, such as those using retrofitted systems like auxiliary heaters. EFB technology is now standard in many small and mid-sized cars with start-stop functionality and is increasingly being used in the electrical systems of hybrid and electric vehicles.

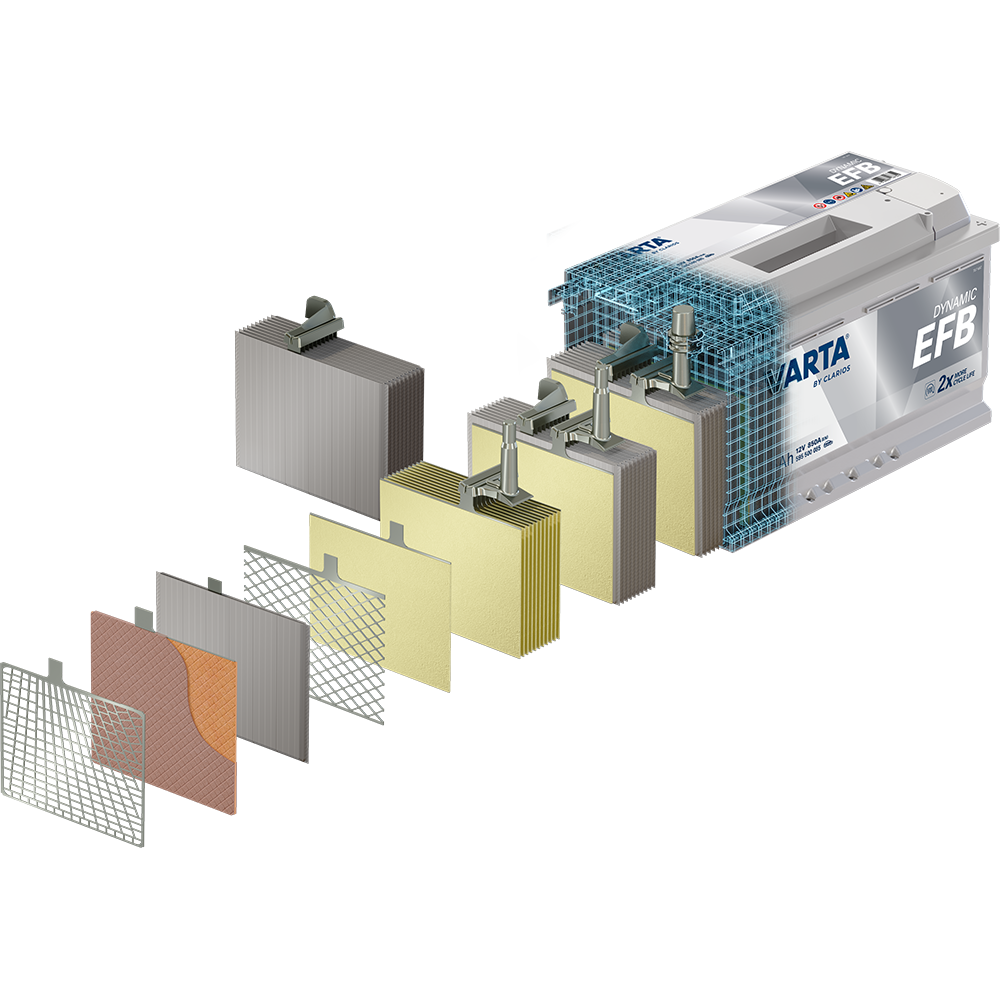

EFB Battery Design & Function

Like conventional wet-cell batteries, EFB batteries use a liquid electrolyte. Their enhanced performance comes mainly from the addition of a polyfleece scrim applied to the surface of the positive plate. This scrim helps stabilise the active material and prevents it from detaching under repeated cycling. As a result, the electrochemical reaction surface remains intact for longer, significantly extending the battery’s service life.

Technical Advancement of the Conventional Wet Battery

From a technical standpoint, the EFB battery is an optimised version of the conventional lead-acid battery. Enhancements such as reinforced grid structures, improved separators with lower internal resistance, and the addition of carbon compounds to the active material lead to better charge acceptance and higher durability. This makes EFB batteries particularly suitable for start-stop vehicles that require frequent engine starts and regular discharging. The internal design enables efficient use of the battery’s capacity without the need to switch to full AGM technology.

Why EFB Batteries Are More Cycle-Resistant

A key feature of EFB batteries is their extended cycle life. Compared to traditional starter batteries, they offer significantly greater durability under frequent charging and discharging.

The following technical improvements contribute to this enhanced performance:

- ✅ Polyfleece scrim on the positive plate stabilises the active material and prevents premature detachment during frequent cycling

- ✅ Reinforced grid structure improves conductivity and extends plate durability

- ✅ Carbon additives in the active material enhance charge acceptance and reduce sulphation

- ✅ Lower internal resistance supports faster recharging during partial state-of-charge operation

- ✅ A robust housing design improves vibration resistance, ideal for installation in the engine compartment

These features allow for up to 270,000 engine starts, making the EFB battery a reliable option for vehicles with basic start-stop systems.

Which Vehicles Are Suitable for an EFB Battery?

EFB batteries can be used across a wide range of vehicle types. Their applications extend from standard passenger cars with start-stop systems to commercial vehicles with high electrical loads. Thanks to their robust construction, high cycle durability, and vibration resistance, these car batteries are not only ideal for urban short-distance traffic but also well suited for demanding commercial use.

Whether an EFB battery is suitable for your vehicle and which specific battery type fits best can be easily determined using the battery finder by entering your vehicle model.

Are EFBs Also Used as Auxiliary Batteries in Electric Vehicles?

EFB batteries are also used in modern electric vehicles, though not as the main drive battery. Instead, they function as 12-volt auxiliary batteries, powering essential systems such as control units, central locking, or emergency call systems independently of the high-voltage system. Thanks to their cycle stability and reliability, EFB batteries are particularly well suited to maintaining stable voltage in the vehicle’s electrical system, especially in EVs equipped with advanced comfort and safety features.

Advantages and Disadvantages of EFB Technology

Whether an EFB battery is suitable for your vehicle depends heavily on how the vehicle is used. For drivers seeking a strong balance between performance, service life, and cost-efficiency, this battery type is a very smart choice. Especially in vehicles with basic start-stop systems and without complex energy recuperation, EFB technology offers many benefits. The following section outlines its key strengths and limitations and when it may be worth considering alternatives such as AGM.

Strengths in Everyday Vehicle Use

- ▸ Longer service life than conventional starter batteries due to improved cycle stability

- ▸ Suitable for frequent engine starts, with up to 270,000 starts achievable under optimal conditions

- ▸ It offers fast charge acceptance, even when partially charged, making it ideal for city driving and short-distance trips.

- ▸ Greater vibration resistance, making them robust for driving on rough roads

- ▸ Good heat resistance, especially with an additional thermal protection sleeve

- ▸ Maintenance-free operation thanks to a sealed housing

This makes EFB batteries well suited for small and mid-sized cars, taxis, emergency vehicles, and increasingly as 12V auxiliary batteries in electric vehicles.

Disadvantages of EFB Batteries

- ▸ It is not suitable for vehicles with brake energy recuperation, where an AGM battery is usually required.

- ▸ Lower cycle life compared to AGM batteries

- ▸ More sensitive to deep discharges than AGM

- ▸ Limited shelf life – long periods of inactivity can reduce performance

- ▸ Higher cost than conventional flooded batteries, but still more affordable than AGM

- ▸ Upgrading to AGM may require technical adjustments (e.g., battery registration with BMS)

All in all, EFB technology offers an excellent combination of performance, durability and economic value. It reliably meets the needs of modern vehicles with start-stop systems and provides a compelling solution, especially in cases where complex energy recovery systems or exceptionally high power demands are not required.

EFB vs. AGM: Battery Comparison

EFB and AGM batteries are both tailored for vehicles with start-stop systems, but they differ in design, performance, and typical use cases. EFB batteries are an improved form of the traditional flooded battery and are well suited for vehicles with moderate electrical demands. AGM batteries, on the other hand, are built for more intensive applications. They perform better in vehicles with frequent regenerative braking, a high number of engine restarts, or complex onboard electronic systems.

Key Technical Differences at a Glance

| Feature | EFB Battery | AGM Battery |

|---|---|---|

| Electrolyte | Liquid, stabilised with polyfleece scrim | Absorbed in fibreglass mat (bound electrolyte) |

| Cycle Life | High (approx. 270,000 engine starts) | Very high (up to 360,000 engine starts) |

| Charge Acceptance | Good | Very good |

| Vibration Resistance | Medium | Very high |

| Maintenance-Free | Yes | Yes |

| Recommended Application | Vehicles with basic start-stop systems, without regenerative braking | Vehicles with regenerative braking, high electrical load |

| Price Level | Medium | Higher |

Can I replace an EFB battery with an AGM battery?

Switching from an EFB to an AGM battery can be worthwhile if your vehicle places particularly high demands on its battery. This applies, for example, to the following situations:

- » Vehicles with regenerative braking systems (recuperation)

- » Numerous electrical consumers such as parking heaters, sound systems or driver assista

Lifespan, Maintenance and Storage of EFB Batteries

How long an EFB battery remains reliable depends not only on its technical design, but also on how it is used and maintained in daily life. In vehicles with start-stop systems, these batteries are exposed to significant strain. However, with proper use, regular care and correct storage, the service life can be significantly extended.

How long does an EFB battery last?

On average, the lifespan of an EFB battery ranges between three and five years. Key influencing factors include driving habits, external conditions such as heat or frost, and the quality of the installed components. The number of electrical consumers in the vehicle also plays a role. When properly used and maintained, an EFB battery can deliver up to 270,000 engine starts, offering a clear advantage over conventional starter batteries.

How to extend battery life

- ▸ Drive the vehicle regularly to avoid deep discharge

- ▸ Switch off electrical consumers when the engine is off (e.g. radio, lights, fan)

- ▸ Use a suitable charger for maintenance charging during longer idle periods

- ▸ Keep battery terminals clean and check regularly for corrosion

- ▸ Monitor the charge level and recharge promptly if necessary

Additionally, regular inspections at a garage can be beneficial, as many service providers offer free battery checks.

Storage and care tips

- ▸ EFB batteries should be stored in a dry, cool and frost-free location, ideally at temperatures between 5 °C and 15 °C.

- ▸ Fully charge the battery before storing

- ▸ Use a charger with a trickle charge function to prevent self-discharge

- ▸ Disconnect the battery if necessary to prevent current leakage and drain

- ▸ Avoid direct contact with metal or moisture to prevent short circuits

With proper storage conditions, an EFB battery can last several months without significant loss of performance, even when not in use.

Conclusion – The EFB Battery at a Glance

The EFB battery is a reliable and high-performance option for many modern vehicles equipped with start-stop systems. It offers significantly greater cycle stability than conventional flooded batteries and is particularly well suited for small to mid-sized vehicles, urban short-distance driving, and commercial vehicles with increased energy demands.

For drivers seeking a solid balance between price, performance and service life, and who do not require the higher specifications of an AGM battery, EFB technology represents a well-informed and practical choice.

Do You Have a Question?

-

Yes, EFB batteries can generally be charged with conventional battery chargers, provided the device is not exclusively designed for AGM profiles. It is important not to use AGM or gel modes, as these often operate at higher voltages (e.g. 14.8 V), which can damage an EFB battery.

-

-

-